PVC CPVC Ala Extrusion Pipe

Ngwọta Nchekwa ọnụ ahịa

1. Mgbakwunye Direct - CaCO3

2. Ngalaba na-ahụ maka mgbidi (nyocha)

3. Akpaaka Thermal Centering (ATC)

4. Sistemụ gravimetric (RGS)

SUPX Direct mgbakwunye - RDA

RDA na-ejide n'aka na mgbakwunye nke ihe na pvc ntụ ntụ ga-eme n'ụzọ ziri ezi na nke na-agbanwe agbanwe.A na-etinyekwa ngalaba RDA na extruder maka ịdoụ ọgwụ siri ike ijikwa ihe na gburugburu ụlọ ọrụ mmepụta ihe.Enwere ike itinye nnukwu ego nke CaCO3 na-enweghị nsogbu nke segregation. Enwere ike itinye ọtụtụ ihe nchịkwa maka ihe mgbakwunye na-enye mgbanwe dị mma maka mmepụta.

Uru nke sistemu RDA

• Enweghị nkewa nke CaCO3 na PVC n'oge njem.

• Ọkụ dị nro.

• Na-ejikọta ego nchekwa ike.

• Mmụba mgbanwe nke eriri extrusion (nhazi ndabere).

• mgbakwunye gravimetric nke ihe mgbakwunye.

• Mpụta dị elu na ọnụego ajụ dị ala.

Ngalaba njikwa mgbidi - ndị nyocha

Ịchịkwa akụkụ nke ọkpọkọ n'oge mmepụta bụ ihe dị mkpa iji mee ka ọkpọkọ dị na nkọwa ndị a họọrọ. Ndị nyocha na-enwe ike ịlele mgbidi ọkpọkọ na dayameta.A nso nke scanners nwere dị iche iche atụmatụ dị, na-ekpuchi ọkpọkọ nha si 10-1600 mm (1/2 "- 60") dayameta.

Uru nke ndị nyocha anyị:

• Ọkpụrụkpụ mgbidi inline na-aga n'ihu na nha dayameta

• Opekempe njikwa ọkpụrụkpụ mgbidi (mbelata oke ibu)

Ebe a na-ekpo ọkụ akpaaka - ATC

ATC na-eme ka o kwe omume ịchịkwa nkesa nke mgbidi mgbidi.The ATC nwere ike ịgbanwe iche na mgbidi ọkpụrụkpụ ma si otú ibelata mmepụta akara mmalite oge, ibu ibu nke ọkpọkọ na ihe scrap.

Sistemụ gravimetric - RGS

Akụkụ bụ isi nke RGS bụ hopper na-atụ.Mgbe ejupụtachara, ihe na-esi na hopper na-atụ egwu na-abanye na extruder. Mbelata ịdị arọ kwa nkeji oge hà nhata ihe oriri nke extruder.A na-atụnyere mmepụta extruder nke enwetara na uru ntinye aka setịpụrụ na usoro nchịkwa ga-edozi ọsọ ọsọ nke extruder (ma ọ bụ ọsọ dosing) iji weta mmepụta na ọkwa achọrọ.Njikwa a na-eme ka mmepụta extruder kwụsie ike n'agbanyeghị mgbanwe na njupụta nke akụrụngwa.

Kama njikwa mmepụta, enwere ike iji akara ngosi mmepụta maka njikwa ọsọ-apụ apụ.N'ọnọdụ ahụ, a na-edobe ịdị arọ ọkpọkọ kwa mita na ọkwa mgbe niile.Mgbe ahịrị ahụ jikọtara ihe nyocha ultrasonic, a na-eji ihe a tụrụ atụ maka ntuzigharị akpaaka nke nha ultrasonic.Nke a na-ewepụ usoro nhazi akwụkwọ ntuziaka na-eri oge.

Usoro njikwa usoro - PCS II

PCS II n'onwe ya bụ usoro njikwa nke enwere ike ijikọ ya na anyocha, ATC, RDA, na RGS.Ụdị nyocha, ATC nausoro gravimetric na-adabere na eriri extrusion.

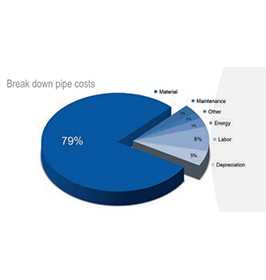

Uru nke ngwọta nchekwa ego anyị

• Ezigbo nloghachi na ntinye ego

• Mbelata oge mmalite na mkpochapụ

• Onye ọrụ enyi na enyi interface maka mkpokọta extrusion akara akara

• Mbelata oke ibu

• Enwere ike iji na akụrụngwa dị.